Bio-based BOPLA (Biaxially Oriented Polylactic Acid) Zaj duab xis

PLA (polylactic acid) yog ib qho polymer nrog lactic acid uas tsim los ntawm kev lom neeg fermentation ua cov khoom siv tseem ceeb.Nws cov khoom siv raw yog txaus thiab tuaj yeem rov tsim dua tshiab, cov khoom yog biodegradable.Tom qab siv, nws tuaj yeem tsim ua carbon dioxide thiab dej ntawm qhov kub siab tshaj 55 ℃ los yog nyob rau hauv qhov kev txiav txim ntawm oxygen enrichment thiab microorganisms, realizing cov khoom ncig nyob rau hauv cov xwm nrog me ntsis cuam tshuam rau ib puag ncig, Yog li ntawd, nws yog ib qho zoo tagnrho ntsuab. cov khoom siv polymer.

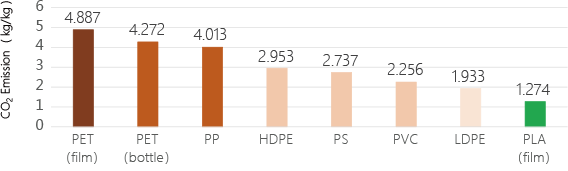

Piv nrog rau lwm txoj kev ua, cov txheej txheem biaxial tensile muab PLA cov ntaub ntawv muaj zog dua thiab thinner zaj duab xis thickness, uas ua rau cov txheej txheem ntawm cov khoom tawg thiab microbial yaig yooj yim dua, yog li nws tuaj yeem txo lub sij hawm biodegradation ntawm cov khoom.Piv nrog cov pob txha pob txha raws li polymers, PLA muaj kev ruaj ntseg biosafety, biodegradability thiab tuaj yeem txo lub zog dependence.Txij li thaum PLA los ntawm bio puag, nws muaj kev cuam tshuam loj rau kev txo cov pa roj carbon monoxide, thiab cov pa roj carbon emissions raug txo los ntawm ntau dua 68% piv nrog cov tshuaj fossil-based plastics.

Hnub tim los ntawm Plastic Europe: Kev sib piv ntawm carbon dioxide emission nyob rau hauv cov txheej txheem polymer ntau lawm

· BOPLA muaj biocompatibility zoo thiab degradation kev ua tau zoo, uas yog ib puag ncig tus phooj ywg.

· Kev ua haujlwm zoo heev thiab zoo folding stability thiab twisting tuav.

· High transparency, low haze, zoo nto gloss thiab zoo heev printing kev kawm.

· Kev ua haujlwm zoo thaum tshav kub kub sealing yam tsis muaj kev kho mob ntxiv.

Cov txheej txheem biaxial stretching tuaj yeem txhim kho cov khoom siv ntawm PLA zaj duab xis zoo, thiab nthuav dav nws daim ntawv thov.Nws tuaj yeem siv rau hauv daim kab xev, ntim khoom noj, ntim khoom tshiab, ntawv laminating, tso tawm cov khoom siv thiab lwm yam, uas yog qhov tseem ceeb rau kev ntim khoom, kev tiv thaiv ib puag ncig thiab txo cov pa roj carbon monoxide.